Most organizations shopping for work order software focus on the obvious capabilities: creating requests, assigning tasks, and tracking completion. These basics matter, but they’re table stakes. Every system handles simple ticketing. The features that actually transform maintenance operations are the ones that most teams overlook during evaluation, only to wish they had them six months after implementation.

Table of Contents

A facilities director managing multiple hospital buildings recently shared his regret about choosing work order software based solely on price and basic functionality. Three years later, his team was drowning in manual workarounds because the system couldn’t handle asset hierarchies, lacked mobile photo capture, and offered no integration with their building automation system. Switching platforms mid-stream would be expensive and disruptive, so they’re stuck with a solution that technically works but constantly frustrates users.

Beyond Basic Ticketing: What Actually Matters

The difference between work order software that digitizes paper forms and platforms that genuinely improve maintenance operations comes down to capabilities that enable smarter workflows, better decisions, and measurable efficiency gains.

Asset hierarchy and relationship mapping. Equipment doesn’t exist in isolation. A chiller connects to an air handler, which serves specific zones that contain individual rooms. When a work order addresses the chiller, technicians need context about the entire cooling system and what downstream equipment might be affected. Work order management software that understands these relationships provides that context automatically. A commercial real estate firm managing 18 office towers found that adding proper asset hierarchies to their work order system reduced their average diagnostic time by 22 minutes per ticket because technicians could immediately see related equipment and recent maintenance history across the entire system.

Customizable priority matrices beyond simple high/medium/low. Real work order prioritization considers multiple factors: safety risk, operational impact, number of people affected, asset criticality, and regulatory requirements. A broken door lock in a secure research lab demands a different urgency than a burned-out light bulb in a storage closet, even if both are “facility issues.” Work order software with configurable priority rules based on multiple criteria ensures critical issues get addressed first, while less urgent tasks queue appropriately.

Comprehensive parts integration. When a technician opens a work order, they should immediately see which parts are required (if it’s a known procedure), current inventory levels for those parts, and the ability to reserve items directly from the work order screen. This integration eliminates the back-and-forth between the work order system and inventory management. A manufacturing facility with significant parts inventory reduced its “waiting for parts” time by 31% simply by integrating inventory visibility into its work order management system.

Robust reporting and analytics capabilities. Every completed work order contains data that reveals patterns, but that information only becomes strategic intelligence when properly analyzed. Work order software should make it easy to identify recurring problems, track cost trends by asset or location, measure technician productivity, and calculate key metrics like mean time to repair and first-time fix rates without requiring manual data export and spreadsheet manipulation.

Mobile Capabilities That Go Beyond Simple Access

Most modern work order software offers mobile apps, but not all mobile implementations deliver equal value. The differences between basic mobile access and truly functional field capabilities are substantial.

Offline functionality for areas without connectivity. Basements, mechanical rooms, and remote locations often have poor or nonexistent cellular coverage. Work order software that requires constant internet connectivity becomes useless in exactly the places technicians need it most. Advanced mobile apps download relevant work order data for offline access, allow technicians to update information and capture photos without connectivity, then sync changes when they return to covered areas.

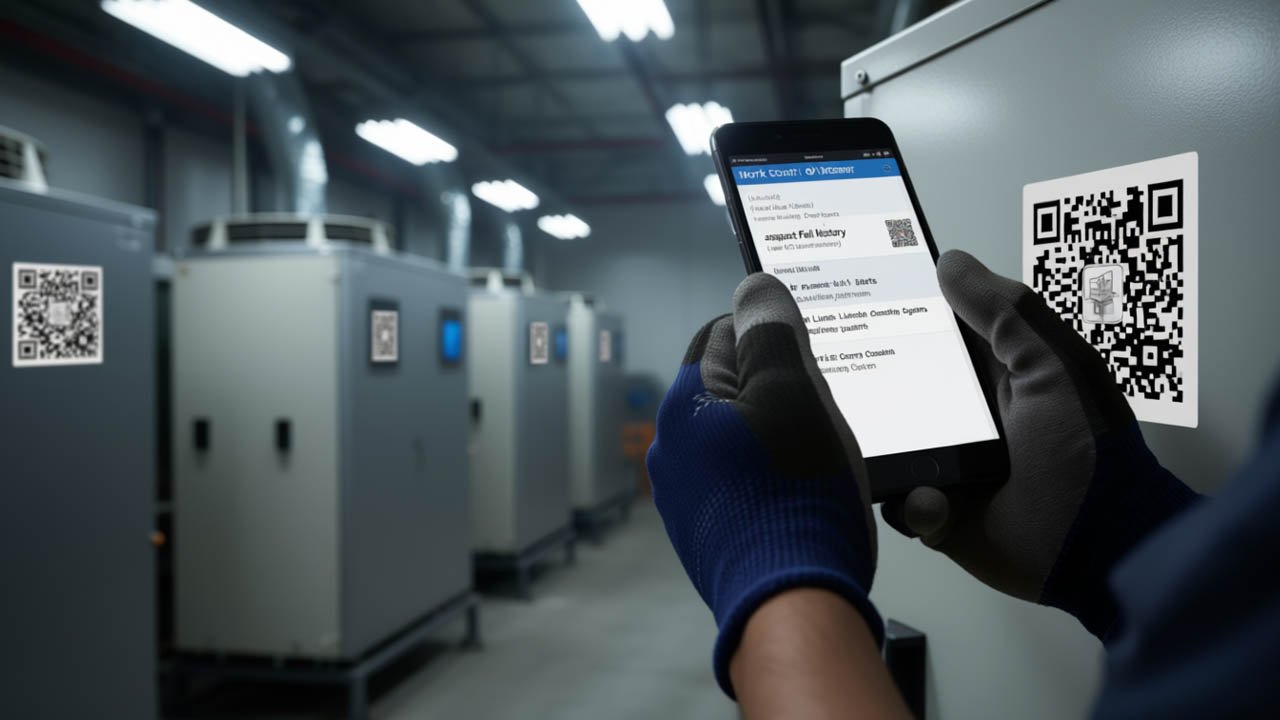

Barcode and QR code scanning for instant asset identification. Manually searching for equipment in a work order system wastes time and introduces errors. Mobile apps with built-in barcode scanning let technicians scan an asset tag and instantly access that equipment’s maintenance history, specifications, and related work orders. A university facilities team added QR codes to their 2,400+ assets and enabled scanning in their maintenance work order software. Time spent locating correct asset records dropped from an average of 3.2 minutes per work order to under 15 seconds.

Voice-to-text for hands-free documentation. When technicians are holding tools or equipment, typing detailed notes is impractical. Mobile work order software with quality voice-to-text capabilities allows technicians to document findings verbally while their hands remain free for work. This feature particularly benefits older technicians who might struggle with small touchscreen keyboards, improving their willingness to provide detailed documentation.

Digital signature capture for approvals and confirmations. Some work requires requester verification that issues are resolved or manager approval before closing. Mobile apps that support signature capture eliminate the need to print work orders for signatures, then manually update the system. A property management company handling tenant work orders cut its average time-to-closeout by 1.8 days by implementing mobile signature capture.

Integration Capabilities That Multiply Value

Work order software delivers maximum value when it connects seamlessly with other systems rather than operating as an isolated platform. Integration capabilities often get minimal attention during evaluation but prove critical during actual use.

Building automation system connectivity. For facilities with BAS platforms, bidirectional integration between building controls and work order systems creates powerful automation opportunities. When a BAS detects a fault condition (temperature out of range, equipment failure, abnormal runtime), it can automatically generate a work order with specific diagnostic information. When technicians resolve the issue and close the work order, the BAS can acknowledge the repair and reset alarms. This integration eliminates manual work order creation and ensures building systems and maintenance operations stay synchronized.

Enterprise resource planning system integration. Organizations using ERP platforms for financial management, procurement, and human resources benefit substantially when their work order management system integrates with those enterprise systems. Labor costs flow automatically from work orders to cost centers. Parts used in repairs update inventory and trigger reordering. Work order data feeds into asset lifecycle analysis. This integration eliminates duplicate data entry and ensures that maintenance information flows into broader business intelligence.

IoT sensor data integration. As facilities deploy more sensors for temperature monitoring, energy management, vibration analysis, and predictive maintenance, work order software that ingests and acts on that sensor data becomes increasingly valuable. Condition-based work orders generate automatically when sensor readings exceed thresholds. Technicians accessing work orders see current sensor data alongside historical trends. A cold storage facility integrated temperature sensors with their work order system and reduced product loss from temperature excursions by 78% because issues triggered immediate work orders before temperatures reached critical levels.

User Experience Details That Impact Daily Adoption

Feature lists tell part of the story, but the daily user experience determines whether work order software actually gets used consistently. Several subtle UX factors dramatically affect adoption rates and long-term satisfaction.

Intuitive navigation that requires minimal training. Work order systems with complex menu structures, buried features, and non-obvious workflows require extensive training and create resistance among users who just want to submit a simple request or complete a straightforward task. Software designed around common user journeys (submit request, check status, complete work, review history) reduces training time and improves adoption. A retail chain evaluated five work order platforms and chose the one that allowed their store managers to submit work orders successfully within 90 seconds of first seeing the interface, without any training.

Configurable dashboards showing relevant information. Different users need different views. Technicians care about their assigned work orders and upcoming scheduled tasks. Supervisors need team workload visibility and completion metrics. Requesters want to track their submitted tickets. Work order management software with role-based dashboards ensures each user sees relevant information immediately upon login rather than having to navigate through multiple screens.

Quick filters and search that actually work. When work order systems accumulate thousands of completed tickets, finding specific historical information becomes challenging. Robust search capabilities that filter by multiple criteria simultaneously (date range, asset, technician, problem type, location) make historical data actually useful rather than technically available but practically inaccessible.

Security and Compliance Features Often Discovered Too Late

Many organizations don’t consider security and audit requirements during initial work order software evaluation, then discover limitations when facing compliance audits or security reviews.

Granular permission controls. Not everyone needs access to all work order information. Technicians might need full access to work orders in their area, but limited visibility elsewhere. Contractors might need access only to their assigned tasks. Vendors might need read-only access to specific asset information. Work order software with detailed permission controls allows organizations to provide appropriate access without compromising security or exposing sensitive information unnecessarily.

Complete audit trails. Regulatory compliance often requires demonstrating who accessed information, what changes were made, and when activities occurred. Work order systems with comprehensive audit logging capture every view, edit, assignment change, and status update with timestamps and user identification. A pharmaceutical manufacturing facility chose work order software partly based on audit trail capabilities because FDA inspections required complete documentation of maintenance activities on production equipment.

Data retention and archiving. Completed work orders contain valuable historical information, but accumulating years of data can impact system performance. Work order management software should offer configurable archiving that moves old records to long-term storage while maintaining searchability and accessibility for compliance purposes.

Cost Considerations Beyond License Fees

Organizations evaluating work order software often focus primarily on licensing costs while overlooking total cost of ownership factors that significantly impact long-term value.

Implementation and configuration effort. Some work order platforms require extensive professional services for setup, configuration, and data migration. Others offer streamlined implementation that organizations can largely handle internally. A facilities management company compared implementation costs across vendors and found them ranging from $8,000 for a straightforward cloud platform to $45,000 for a complex on-premise system requiring significant customization.

Training requirements and user adoption timelines. Complex systems with steep learning curves require substantial training investment and extended adoption periods where productivity temporarily drops as users learn new workflows. Intuitive platforms minimize training costs and reach full adoption faster. Calculate both direct training costs and the indirect cost of reduced productivity during transition periods.

Ongoing maintenance and upgrade effort. Cloud-based work order software typically includes automatic updates and infrastructure maintenance as part of subscription fees. On-premise solutions require internal IT resources for server maintenance, security patching, backup management, and version upgrades. These ongoing costs can substantially exceed initial licensing differences over multi-year timeframes.

Making the Right Choice for Your Operation

Selecting work order software that will serve your organization well for years requires looking beyond feature checklists to consider how the platform will support your specific operational needs and workflows.

Start with your most painful problems. What aspects of your current work order process create the most frustration or inefficiency? If technicians waste significant time hunting for asset information, prioritize systems with strong asset management integration. If work orders languish unassigned, focus on platforms with intelligent routing and assignment. If you struggle to prove maintenance value to leadership, emphasize reporting and analytics capabilities.

Involve actual users in evaluation. The people who will use work order software daily should participate in vendor demos and trial periods. Their practical perspective often identifies usability issues or missing capabilities that evaluation committees focused on features and pricing might overlook. A healthcare system lets its maintenance technicians test three finalist platforms for two weeks each before making a selection, resulting in significantly better adoption than their previous vendor-selected implementation.

Plan for growth and evolution. Choose work order management software that can scale as your operation grows and adapt as your needs evolve. Adding locations, users, or assets shouldn’t require platform replacement. Integration capabilities should allow you to connect new systems as your technology ecosystem expands.

The right work order software becomes invisible infrastructure that removes friction from daily maintenance work while providing visibility into operational performance. The wrong choice creates constant workarounds, user frustration, and missed opportunities to leverage maintenance data strategically. Investing time upfront to evaluate capabilities that truly matter for your specific operation delivers returns for years through improved efficiency, better asset performance, and maintenance operations that contribute measurably to organizational success.